【Steel Seal Number】:there are steel seal number on the surface of c.v. joint. it not only could easy to identification information of product, but also could retrospect date of manufacture.

【Steel Seal Number】:there are steel seal number on the surface of c.v. joint. it not only could easy to identification information of product, but also could retrospect date of manufacture.

【Double Drc Of Ball Channel】:The reason of double arc design because When the vehicle is started or braked, the gap between the steel balls and the ball channels will cause the steel balls to move. If there is no stress point contact between the steel ball and the channel, it will lead to abrasion of the steel ball surface and the channel surface. The double arc design changes the surface to surface contact to point to point contact, reducing the abrasion of ball channel and steel ball effectively, and improving the service life of ball cage and half shaft.

【Double Drc Of Ball Channel】:The reason of double arc design because When the vehicle is started or braked, the gap between the steel balls and the ball channels will cause the steel balls to move. If there is no stress point contact between the steel ball and the channel, it will lead to abrasion of the steel ball surface and the channel surface. The double arc design changes the surface to surface contact to point to point contact, reducing the abrasion of ball channel and steel ball effectively, and improving the service life of ball cage and half shaft.

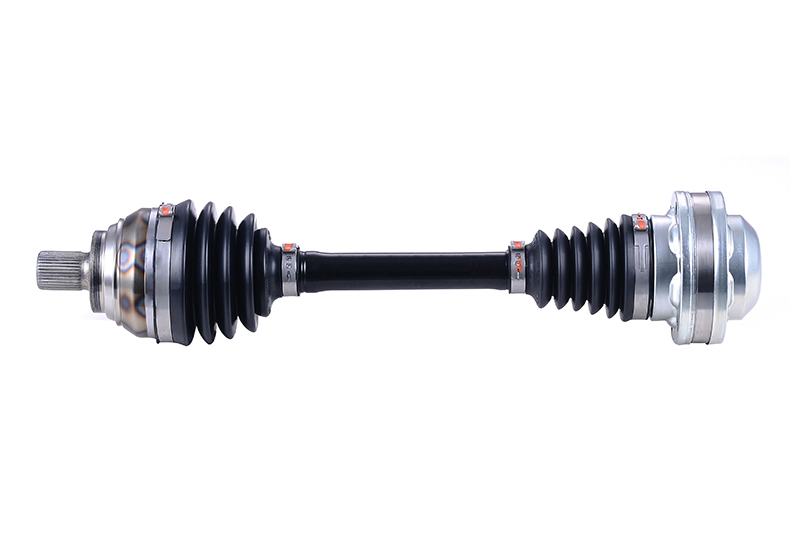

【TPEE Boots】:The original material of C.V. Joint Boot from DU PONT company in U.S.A. The equipment of producing from Germany. The wall thickness of the boot is consistent, and there is no abnormal sound during extrusion, which has good tensile property. The TPEE boot can withstand high temperature + 160 ℃ and bottom temperature - 60 ℃. The service life of the product is three times that of the rubber general C.V. Joint boot.

【TPEE Boots】:The original material of C.V. Joint Boot from DU PONT company in U.S.A. The equipment of producing from Germany. The wall thickness of the boot is consistent, and there is no abnormal sound during extrusion, which has good tensile property. The TPEE boot can withstand high temperature + 160 ℃ and bottom temperature - 60 ℃. The service life of the product is three times that of the rubber general C.V. Joint boot.

【OETIKER Clamp】:The brand of clamp is used “OETIKER” which is the famous brand in the world. Observe the cross-section of the clamp, there is no rag on the sides of clamp, and conduct round edge treatment to minimize the damage to the boot. Thus, ensure the each drive shaft has excellent quality effectively.

【OETIKER Clamp】:The brand of clamp is used “OETIKER” which is the famous brand in the world. Observe the cross-section of the clamp, there is no rag on the sides of clamp, and conduct round edge treatment to minimize the damage to the boot. Thus, ensure the each drive shaft has excellent quality effectively.

【Grease】:The content of molybdenum disulfide (MoS2) in grease of the axle shaft exceeds 2.5%.Its excellent wear resistance and high and low temperature resistance effectively ensure that the axle shaft assembly can work normally at high speed for a long time.

【Grease】:The content of molybdenum disulfide (MoS2) in grease of the axle shaft exceeds 2.5%.Its excellent wear resistance and high and low temperature resistance effectively ensure that the axle shaft assembly can work normally at high speed for a long time.