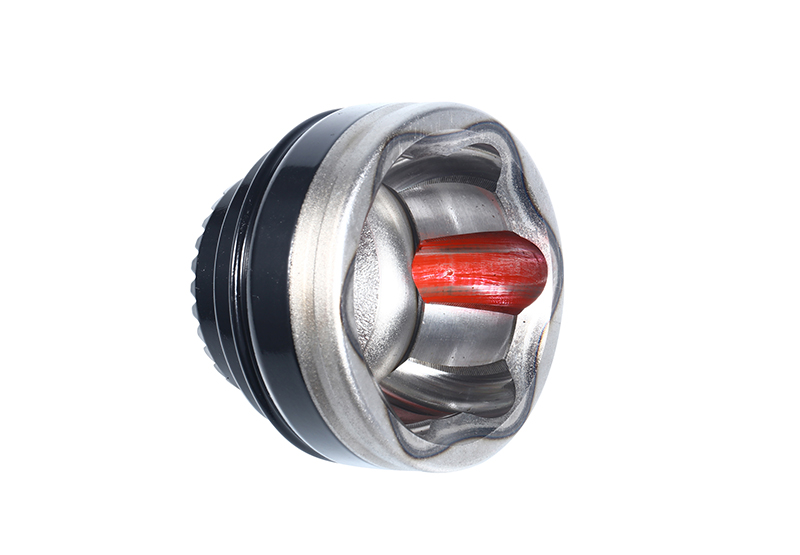

【Double Arc Of Ball Channel】:The reason of double arc design because When the vehicle is started or braked, the gap between the steel balls and the ball channels will cause the steel balls to move. If there is no stress point contact between the steel ball and the channel, it will lead to abrasion of the steel ball surface and the channel surface. The double arc design changes the surface to surface contact to point to point contact, reducing the abrasion of ball channel and steel ball effectively, and improving the service life of ball cage and half shaft.

【Double Arc Of Ball Channel】:The reason of double arc design because When the vehicle is started or braked, the gap between the steel balls and the ball channels will cause the steel balls to move. If there is no stress point contact between the steel ball and the channel, it will lead to abrasion of the steel ball surface and the channel surface. The double arc design changes the surface to surface contact to point to point contact, reducing the abrasion of ball channel and steel ball effectively, and improving the service life of ball cage and half shaft.

【TPEE Boots】:The original material of C.V. Joint Boot from DU PONT company in U.S.A. The equipment of producing from Germany. The wall thickness of the boot is consistent, and there is no abnormal sound during extrusion, which has good tensile property. The TPEE boot can withstand high temperature + 160 ℃ and bottom temperature - 60 ℃. The service life of the product is three times that of the rubber general C.V. Joint boot.

【TPEE Boots】:The original material of C.V. Joint Boot from DU PONT company in U.S.A. The equipment of producing from Germany. The wall thickness of the boot is consistent, and there is no abnormal sound during extrusion, which has good tensile property. The TPEE boot can withstand high temperature + 160 ℃ and bottom temperature - 60 ℃. The service life of the product is three times that of the rubber general C.V. Joint boot.

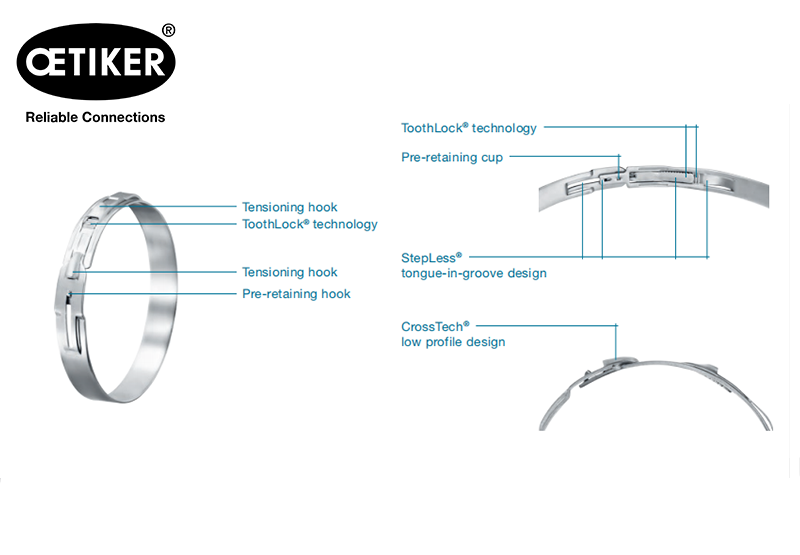

【OETIKER Clamp 292】:ToothLock technology: very high and permanent compression, superior radial load performance, highly pressure and expansion resistant

【OETIKER Clamp 292】:ToothLock technology: very high and permanent compression, superior radial load performance, highly pressure and expansion resistant

CrossTech: ultra low profile design, very low imbalance on rotating parts

StepLess: uniform compression, powerful all-round seal, withstands thermal stress, shock- and vibration-resistant

Burr-free strip edges: reduced risk of damage to parts being clamped

Pre-retaining cup: visual clamp closure verification

Assembly-friendly and reliable: extended diameter range, time-saving and process reliable assembly

【Surface Treatment】:The production process of the axostyles is completely implemented in accordance with the standard of the original accessories for loading. The technical level of the friction welding process has reached the international standard. The product appearance protection treatment process "electrostatic powder coating", English name: electrostatic powder coating, has reached the EU environmental protection standard.

【Surface Treatment】:The production process of the axostyles is completely implemented in accordance with the standard of the original accessories for loading. The technical level of the friction welding process has reached the international standard. The product appearance protection treatment process "electrostatic powder coating", English name: electrostatic powder coating, has reached the EU environmental protection standard.